China leading palm oil mill plant machine manufacturer and supplier

Email:info01@cnoilmachine.com

Building a palm oil plant requires determining the core direction based on production capacity, and then proceeding through key aspects such as site selection compliance, process equipment, environmental approvals, and investment costs. Below is a comprehensive set of key points for plant construction consultation, adaptable to different scales of plant needs:

Determine Core Production Capacity: Different capacities correspond to different processes and investments. Small plants are suitable for 1-20 tons/day (TPD), adaptable to intermittent refining processes, with simple equipment and low investment, suitable for small-scale regional processing needs. Medium to large plants (20-50 TPD) can choose semi-continuous refining processes. Large plants (50-600 TPD) require fully continuous refining processes.

Select Plant Type:You can choose a pressing plant (for fresh palm fruit, requiring fermentation, fruit removal, and other pressing processes) or a refining and extraction plant (for crude oil, the core is degumming, deacidification, and other refining processes, as well as the extraction of linseed and stearin). If close to palm fruit growing areas, an integrated pressing and refining plant can be built. If far from raw material production areas, focus can be placed on refining, extraction, and packaging.

Core Site Selection Requirements: The site must avoid sources of pollution such as harmful gases and smoke. Plant roads should be paved with hard materials such as concrete to prevent water accumulation and dust. Transportation convenience must also be considered, with proximity to transportation hubs for easy transport of raw materials (such as palm fruit bunches and crude oil) and finished products. If storage tanks are involved, sufficient safety distances must be reserved, and protective facilities such as dikes must be installed.

Functional Zoning of the Plant Area: The area must be divided into raw material storage, production workshops, finished product storage, hazardous waste storage areas, and wastewater treatment areas, with production areas separated from living areas. For example, a small refinery needs to reserve approximately 3,000 square meters of land, while large projects require supporting facilities such as storage tank areas, packaging workshops, and distribution centers.

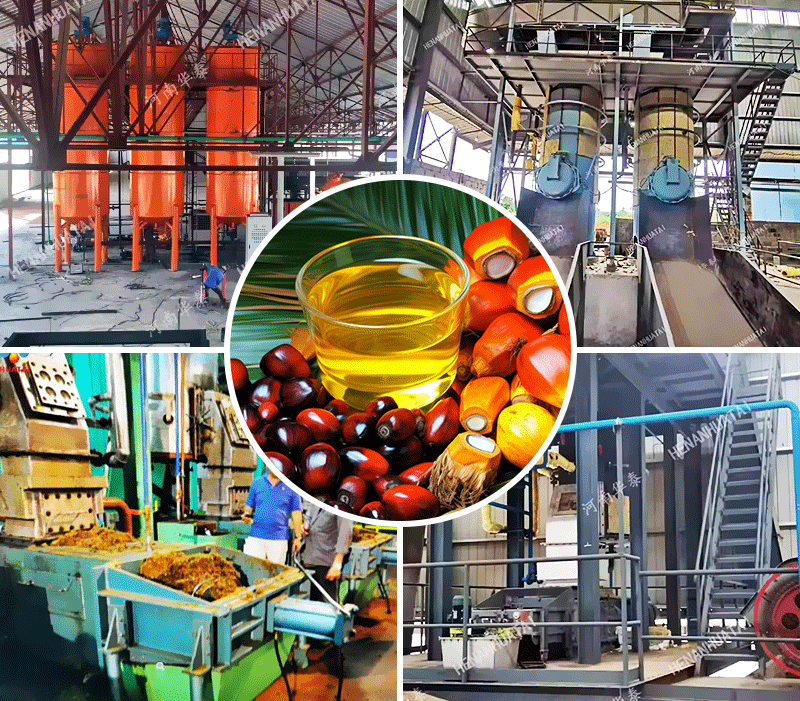

Core Processes: The pressing plant process is: sterilization → fruit removal → crushing → pressing → oil clarification → vacuum drying; the refining and fractionation plant process is: degumming → deacidification → decolorization → deodorization → fractionation. The fractionation stage can separate palm oil into soft and hard oils by controlling the temperature, adapting to different application scenarios.

Key equipment includes: the pressing stage requires fermentation tanks, rotary drum decanters, twin-screw oil presses, and plate and frame filters; the refining stage requires alkali refining units, decolorization towers, and deodorization towers; and the fractionation stage requires cooling crystallizers and membrane filters. Equipment selection should be based on production capacity. For example, large plants can choose highly automated continuous equipment, while small plants can choose simple decanters to reduce costs.

Production License: An edible vegetable oil production license is required, with the application unit being edible vegetable oil (semi-refined/fully refined).

Environmental Approvals: An environmental impact assessment is required in advance. Waste gas must be treated using processes such as "water spraying + biological deodorization + secondary activated carbon adsorption" before being discharged. Production wastewater must be pre-treated in self-built facilities and then discharged into the sewage treatment system after meeting standards. Hazardous waste must be handled by a qualified unit, and an emergency response pool and environmental risk emergency plan must be established.

Other Qualifications: Business registration and tax registration are required. If importing or exporting raw materials or finished products is involved, relevant customs filing procedures are also required.

Cost Differences Based on Scale: Small refineries require lower investment, while large projects require higher investment.

Cost Structure: Mainly includes equipment procurement costs, plant construction/ The costs include rental fees, investment in environmental protection facilities, raw material reserves, and subsequent labor and maintenance costs. Large-scale projects also require reserve funds for the distribution(distribution link/process).

Process Control: Real-time monitoring of crude oil and indicators such as acid value and peroxide value at each stage of refining. Deacidification and deodorization are key control points in refining, requiring precise control of alkali dosage, deodorization temperature (220-260℃), and time.

Factory Inspection: Equipment such as a Lovibond colorimeter, analytical balance, and gas chromatograph is required to inspect the color and solvent residue of the finished product to ensure compliance with national standards.

Raw Materials and Storage: The use of raw materials mixed with non-edible oils is strictly prohibited. Crude oil must be stored in a low-temperature, sealed environment to prevent oxidative rancidity. Hollow palm fruit bunches can be recycled as biofuel, and palm kernels can be processed and utilized separately to improve resource utilization.

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.