China leading palm oil mill plant machine manufacturer and supplier

Email:info01@cnoilmachine.com

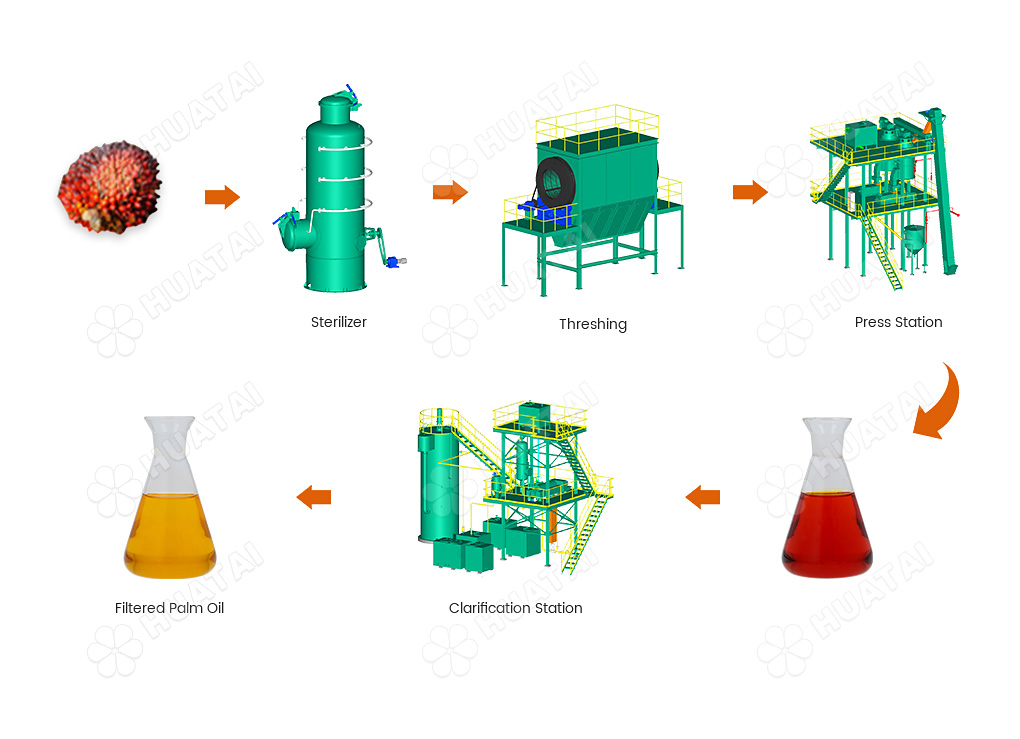

Huatai Palm Oil Milling Machine

The fruit bunches are sent to the primary pressing plant within 24 hours after picking (to prevent the increase of FFA). (2) Steaming: Sterilize at 150℃ for 2 hours and cook the fruit bunch stems. (3) Peel the fruit, open the machine-peeling machine, separate the fruit bunch stems, burn the stems as fertilizer, and send the fruit to the silo. (4) Pressing: Screw press. The cake is squeezed out from the head of the machine, containing the fruit core (not cracked, containing palm kernel oil), and the liquid part flows out from the bottom. After filtering, it is sent to the butterfly centrifuge to obtain crude palm oil. (5) Pressing palm kernel oil, the cake obtained in step (4) is sent to the mesh separation port. a) The crushed and squeezed fruit flesh fiber is processed to produce fiberboard and paper; b) The fruit core is sent to the crusher to crack the shell and separate the kernel, which is used as fuel; c) The kernel is passed through the press, filter and butterfly separator to obtain crude palm kernel oil. The oil yield from fresh oil palm fruit is 20% crude palm oil and 2% crude palm kernel oil. Crude palm oil is orange-red and semi-liquid. Surface density (50°C): 0.8896-0.8910, Saponification value (mgkoH/g oil): 190-202, Iodine value (gz²/100g oil): 501-549, Freezing point (°C): 30-39, Unsaponifiable matter (%): 0.15-0.99, Fatty acid distribution (%): C12O: 0.1-0.4, C14O: 1.0-1.4, C16O4: 0.9-47.5, C161: 0-0.5, C18O: 3.8-4.8, C181: 36.4-41.2, C182: 0.2-11.6, C1830-0.5, C20O: 0-0.8.

Crude palm oil mills in Malaysia (especially West Malaysia) have strict environmental protection requirements. For example, a local palm oil mill, built in 1975, initially invested RM15 million, which grew to RM40 million over 20 years. The mill covers approximately 40 hectares. Currently, a similarly sized mill (crushing 900-1000 tons of palm oil daily) would require an investment of US$7-8 million, plus investment in environmental protection facilities. The mill employs 85 people (each earning RM20-30 per day). The current cost of crude palm oil is RM600 per ton, and processing costs are around RM25 per ton.

Huatai Palm Oil Mill Plant Machine Offers Complete Palm Oil Mill Plant Solutions. In addition, we also provide professional technical team to design the whole palm oil mill plant, help customers maximize the the commercial profits by making most use of the by-products produced during the process of palm oil manufacturing. We can provide a comprehensive and professional turnkey palm oil mill plant project. Henan Hutai machinery have experienced engineers who can help customers design detailed palm oil production lines, provide installation services and guide the use of machines, truly achieve personalized services, and meet customers' all-round needs for palm oil processing. If you need any palm oil processing machines and palm kernel oil processing machine, palm oil refining machine please contact with us.

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.