China leading palm oil mill plant machine manufacturer and supplier

Email:info01@cnoilmachine.com

Turnkey Palm Oil Plant Project Service

Site planning → Equipment customization → Installation → Operator training

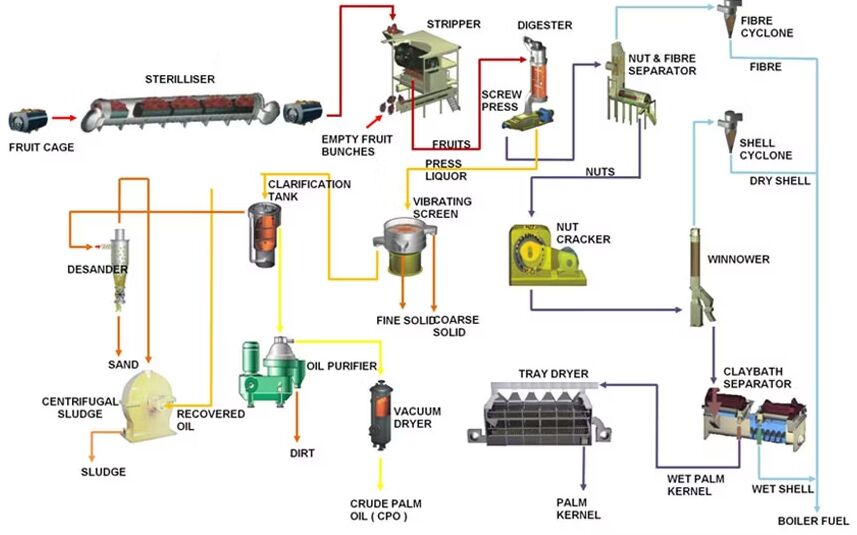

1.palm fruit/bunch → sterilization → threshing → digesting → clarification → purification → CPO

→ refining → decolorizing → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

2.palm kernel →depericarper → crushing → pressing → CPKO → refining → RBDPK oil , RBDPK olein & RBDPK stearin

1. Our company adopts hydraulic segmented discharge in palm fruit unloading, cleaning, storage platform;

2. Palm fruit oil press machine adopts double helix hydraulic continuous discharging, greatly improving the production efficiency;

3. The use of diesel generator and steam turbine generator is more environmental protection and energy saving, electricity power for production and life;

4. Our water treatment system, through sedimentation, filtration, dosing process, ensure the quality of the water, also ensure the quality of palm oil;

5. Adopting the remote substation technology, more energy efficient, improve the production efficiency.

Specifications: 10T/H,30T/H,45T/H,60T/H,80T/H,100T/H(TON/HOUR);

As a professional manufacturer of palm oil processing equipment and technical solutions, we provide:

High-efficiency palm fruit press machines

Complete palm oil production line (cooking oil production line) equipment

Customized solutions for large/medium/small-scale vegetable oil processing plants.

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.